Mechanical Properties Of Ceramic Matrix Composites

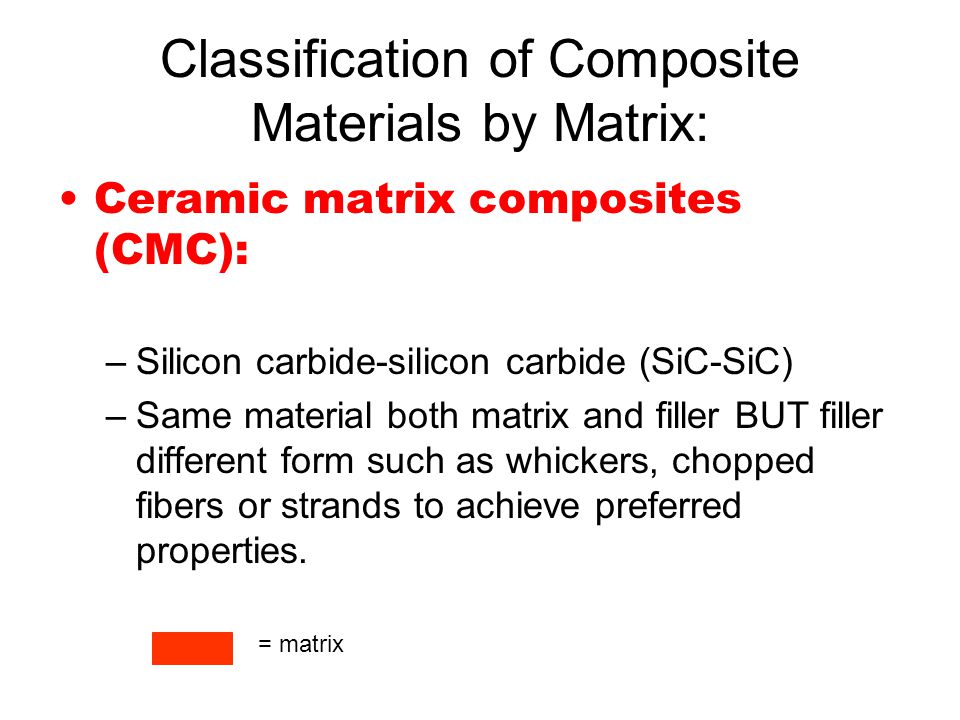

Ceramic matrix with fibers or whiskers as reinforcement.

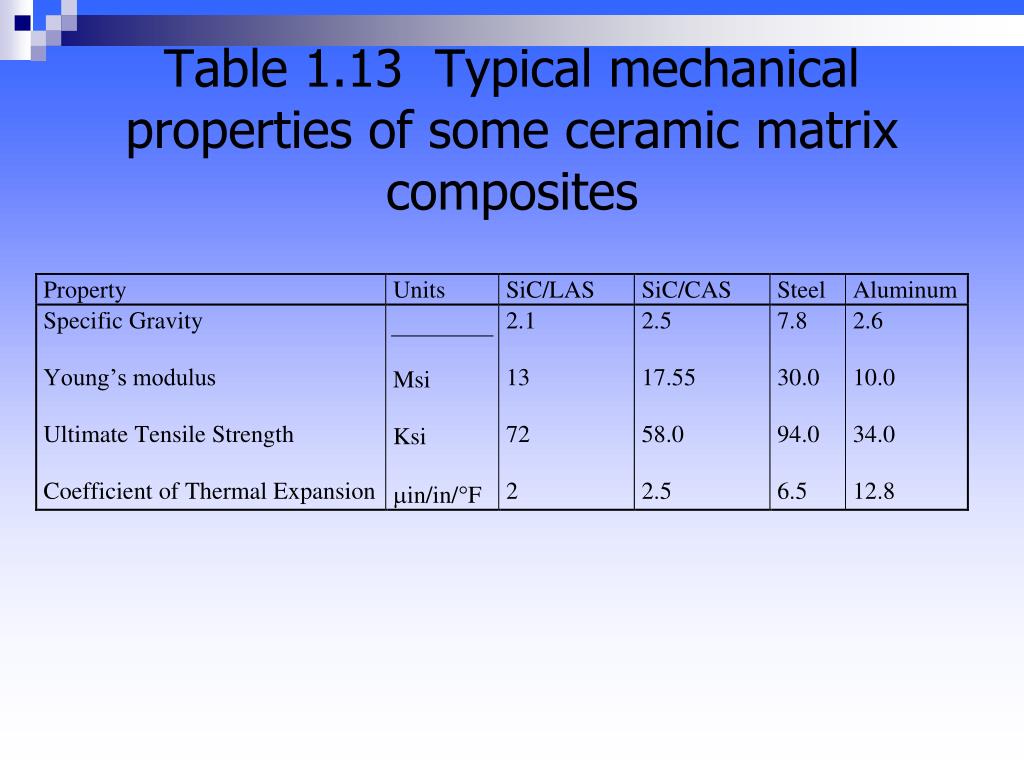

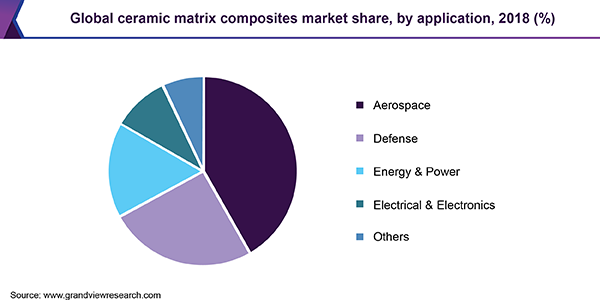

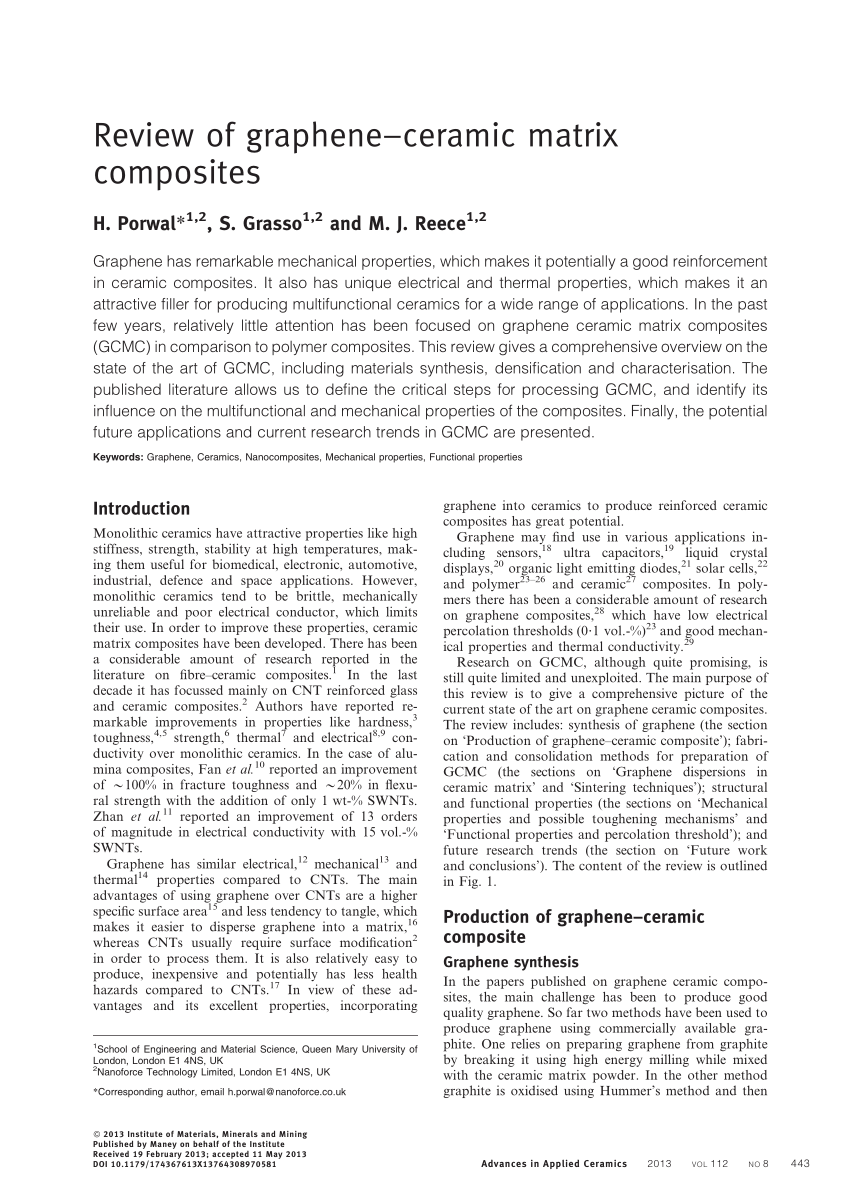

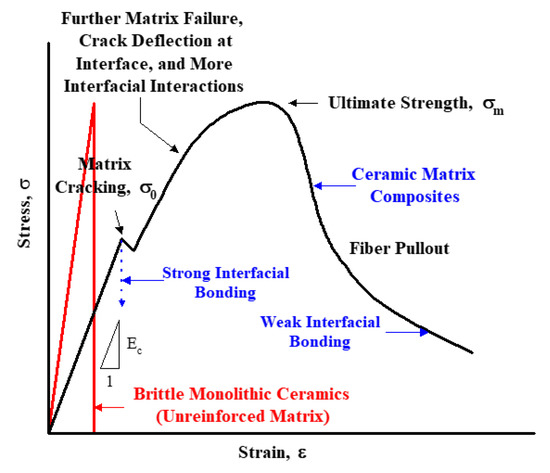

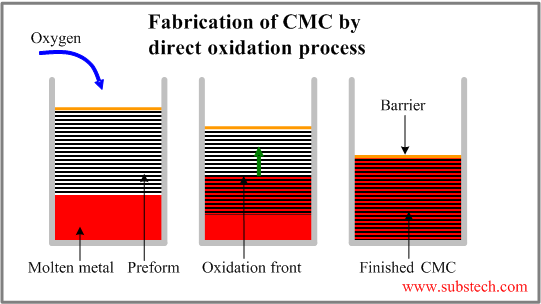

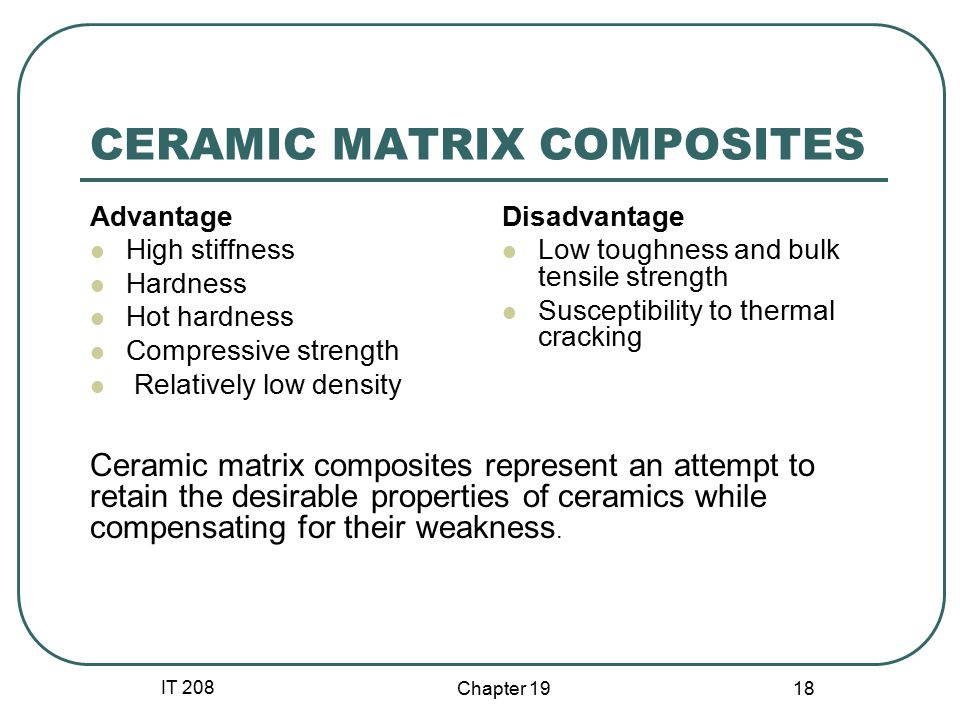

Mechanical properties of ceramic matrix composites. With the rising demand for high performance aero engines ceramic matrix composites with low density and excellent high temperature behavior have been extensively studied to meet the growing. The porosity is varied through impregnation and pyrolysis of a ceramic precursor solution. Cross sections left and fracture surfaces right of carbon fiber reinforced siloxanes depending on densification fiber tenax hta5411 coated with 2 5 mass phenolic resin bakelite 9691 fw calcined at. Under load the ceramic matrix cracks like any ceramic material at an elongation of about 0 05.

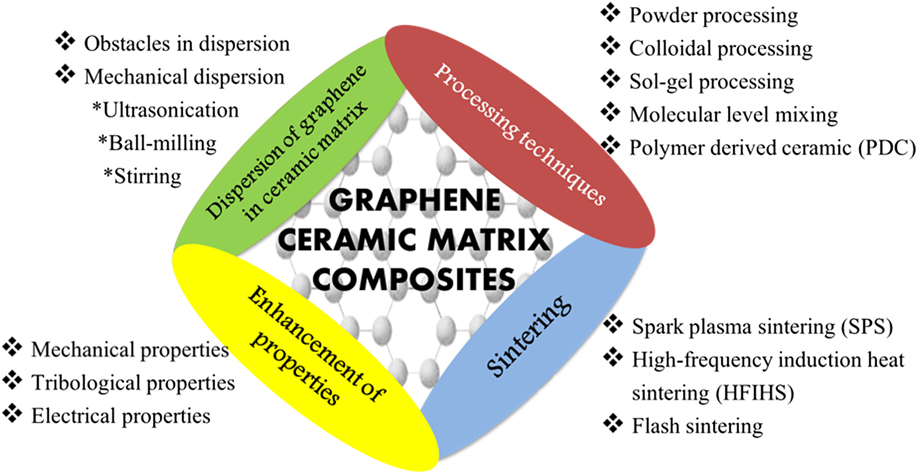

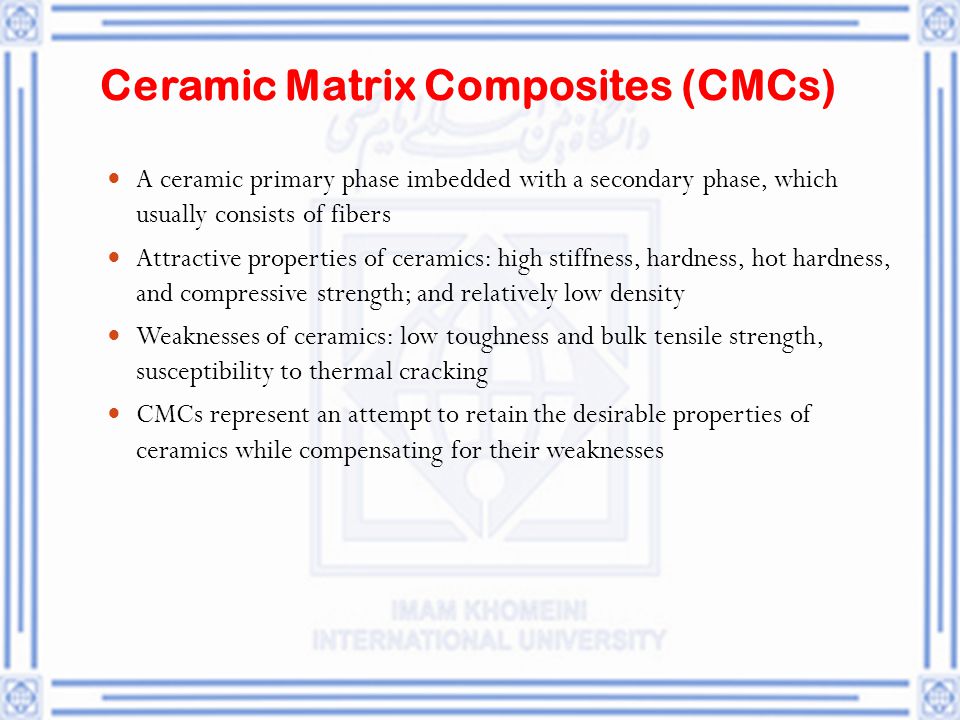

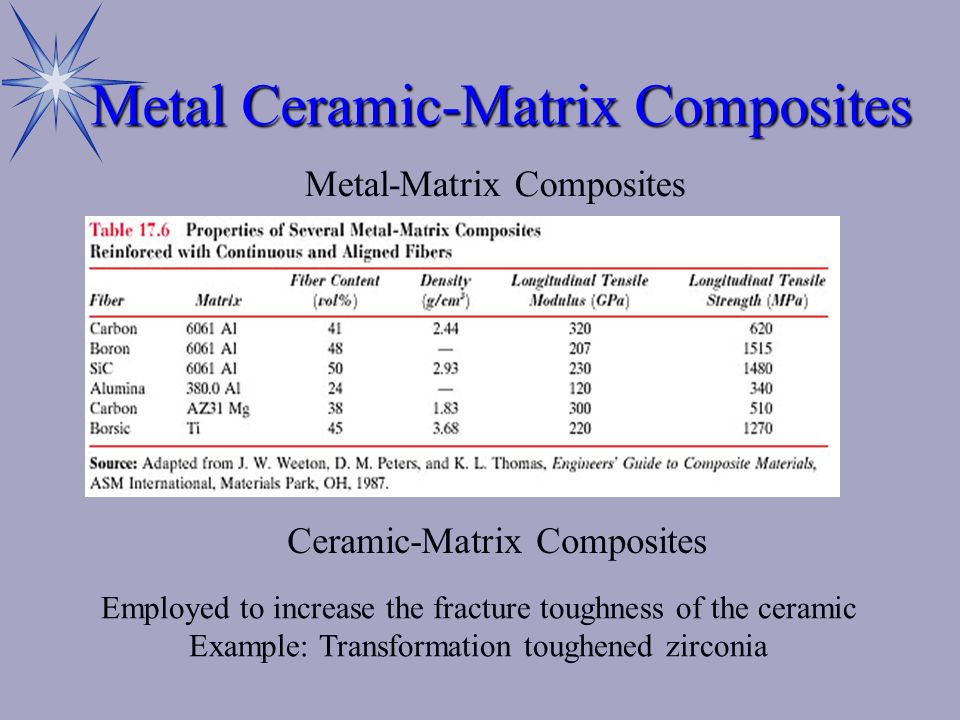

Cmcs are materials showing a chemically or physically distinct phase in large proportion 5 dispersed in a continuous matrix exhibiting specific final properties. In cmcs the embedded fibers bridge these cracks see picture. In the former mechanical keying can lead to interfacial bonding which makes a considerable contribution to the strength of the interface from the surface roughness of the fibers. In fiber reinforced ceramic matrix composites the fiber and matrix are combined at the interface by i mechanical bonding interlocks and ii chemical bonding.

Mechanical tests are performed to assess the role of the matrix in both matrix dominated and fiber dominated loading configurations. Crossref yutai katoh ceramic matrix composites in fission and fusion energy applications advances in ceramic matrix composites 10 1016 b978 0 08 102166 8. Lili li zhenhai xia role of interfaces in mechanical properties of ceramic matrix composites advances in ceramic matrix composites 10 1016 b978 0 08 102166 8 00015 3 355 374 2018. The effects of matrix porosity on the mechanical properties of an all oxide ceramic composite are investigated.

Mechanical properties of composites depending on the number of densification cycles fiber tenax hta5411 coated with 2 5 mass phenolic resin bakelite 9691 fw calcined at 1000 c matrix wacker silres h62c calcination temperature 750 c. Ceramic matrix with a second phase as reinforcement such as addition of partially stabilized zirconia to increase mechanical properties of stabilized zirconia. Ceramic composites can be considered basically in two groups. Abstract advanced ceramics exhibit a combination of properties.

In comparison microwave absorption structures with ceramic as the matrix exhibit satisfactory microwave absorption properties and unique superiorities of mechanical properties which include relatively high hardness flexural strength elastic modulus and high temperature resistance. Mechanical properties basic mechanism of mechanical properties.