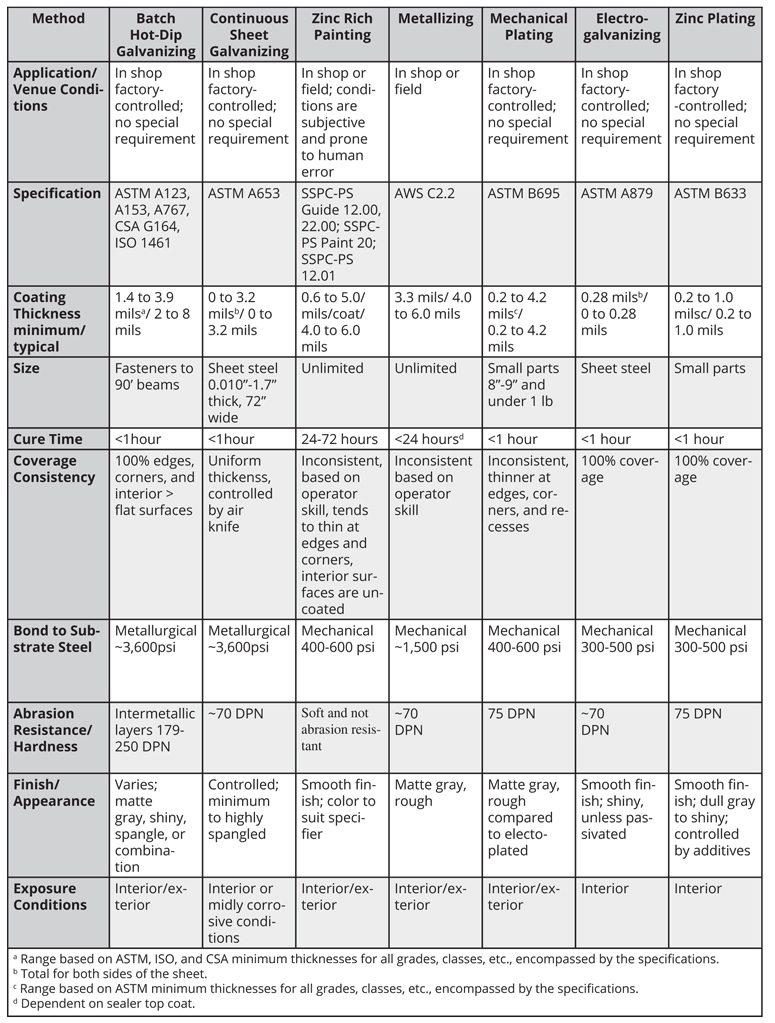

Mechanical Zinc Plating Equipment

Mechanical zinc plating is accomplished by tumbling small parts in a drum with zinc and proprietary chemicals.

Mechanical zinc plating equipment. And since it s added to the final stagnant rinse at low concentrations 1 to 8 by volume no additional equipment is required. Mechanical zinc plating and galvanizing systems offer the perfect solution when the potential for hydrogen embrittlement exists. Zinc plating configuration form. Additionaly compared to hot dip galvanizing mechanical plating does not require threads to be chased after plating.

Mechanical plating also known as peen plating mechanical deposition or impact plating is a plating process that imparts the coating by cold welding fine metal particles to a workpiece. It is commonly used to overcome hydrogen embrittlement problems. Mechanical galvanization is the same process but applies to coatings that are thicker than 0 001 in 0 025 mm. Small iron and steel parts usually limited in size to about 8 9 inches 200 300 mm and weighing less than one pound 0 5 kg are cleaned and flash coppercoated before loading into a plating barrel.

Steel of any hardness can be processed quickly and effectively offering the same high protection as conventional electroplated zinc deposits.

.jpg)