Minimum Bend Radius Sheet Metal Aluminum

It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii.

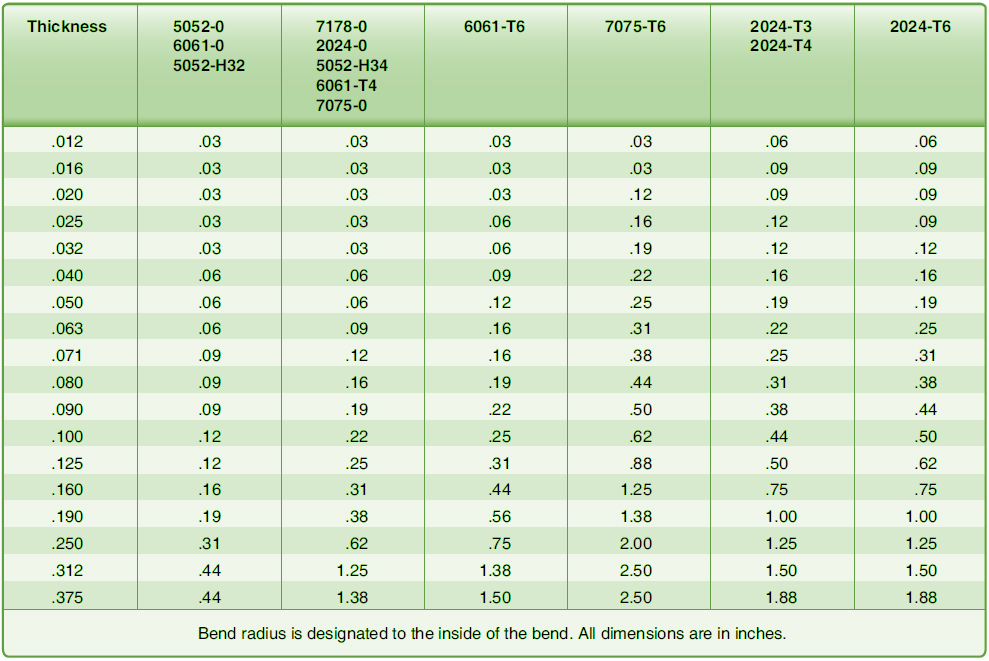

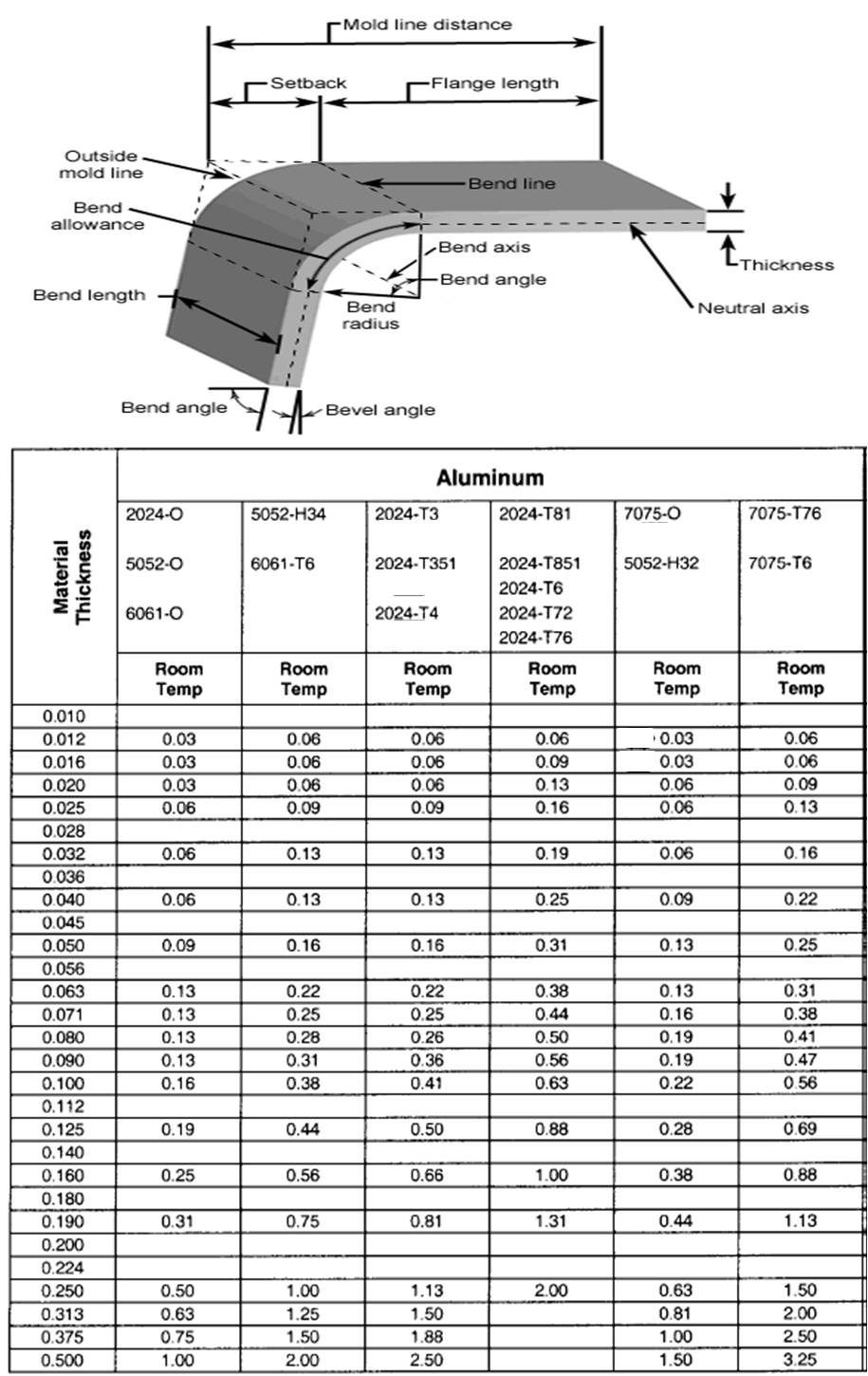

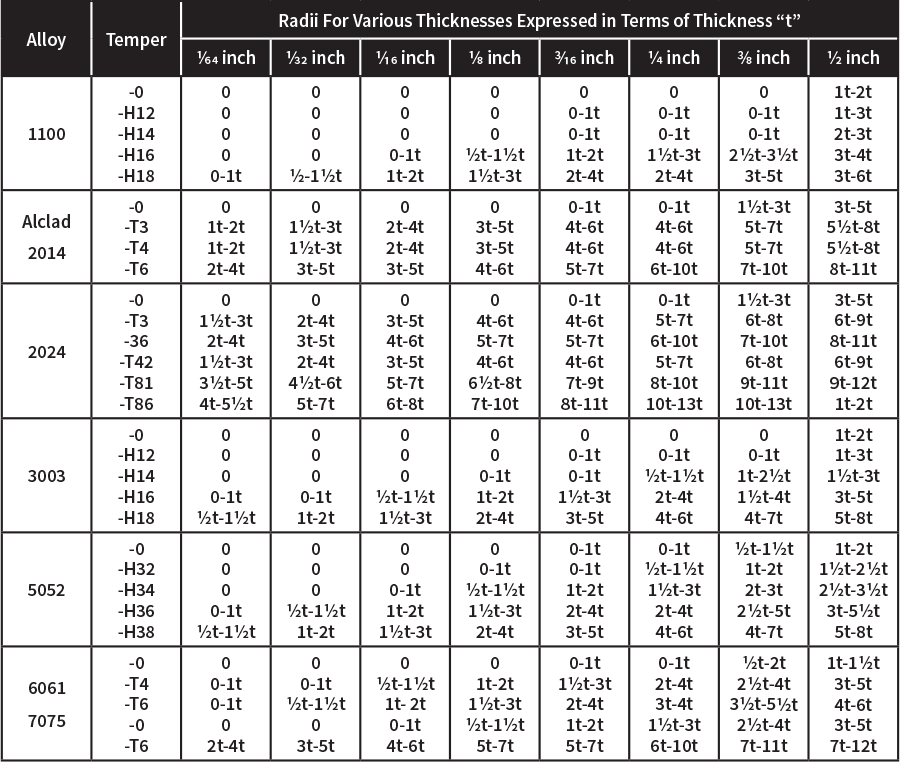

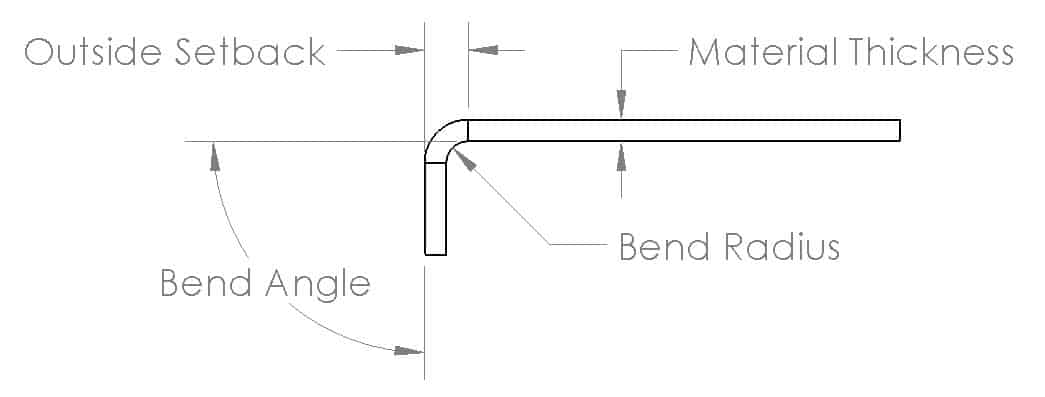

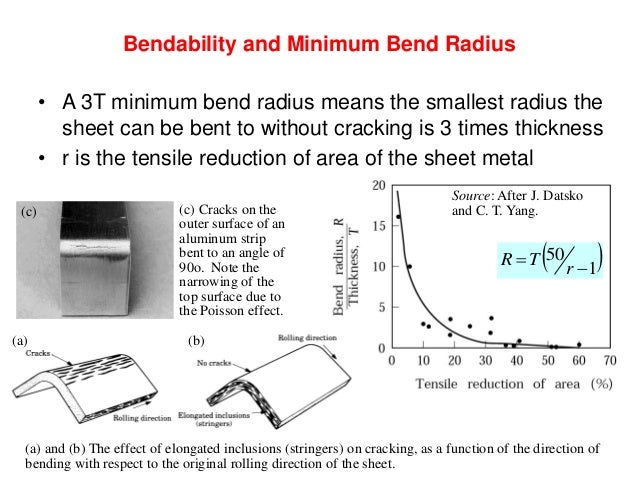

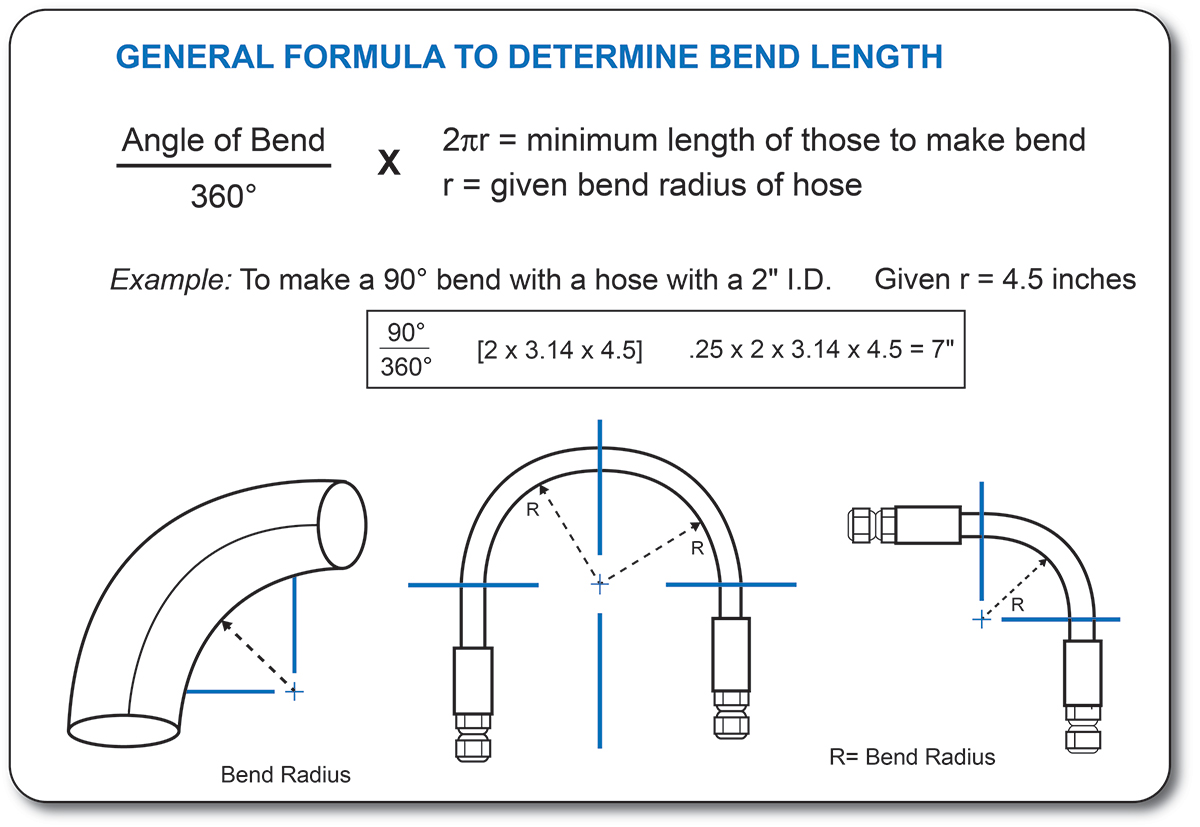

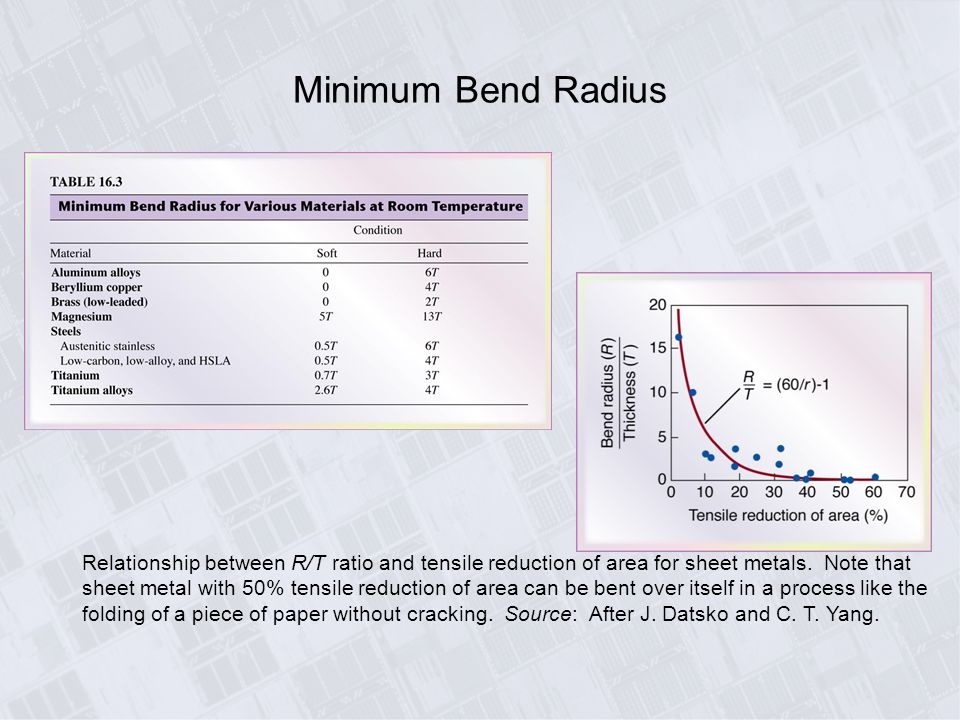

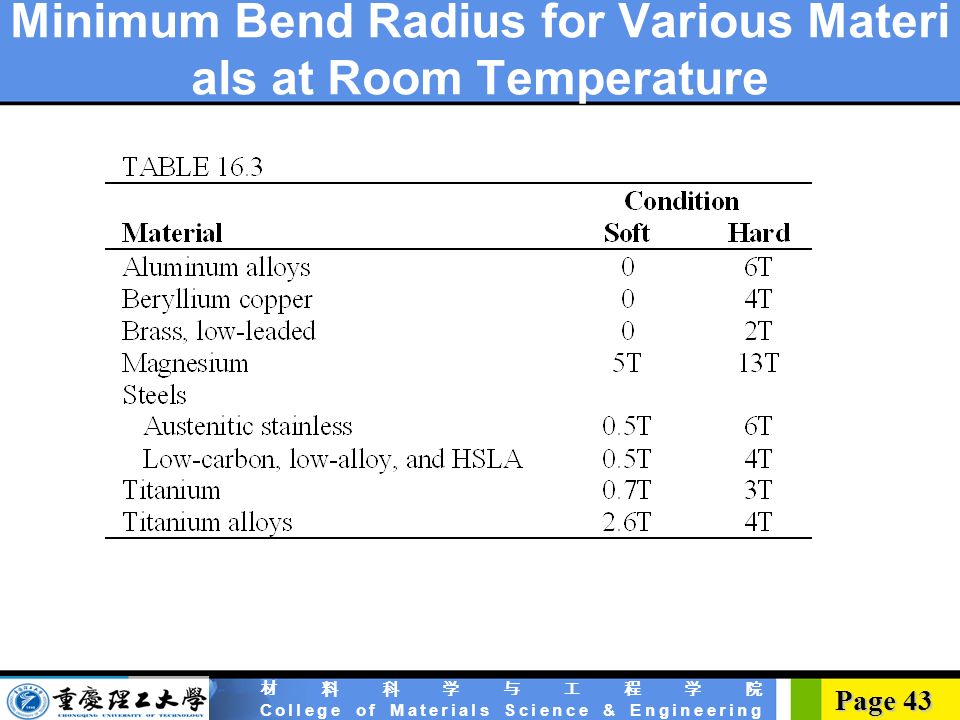

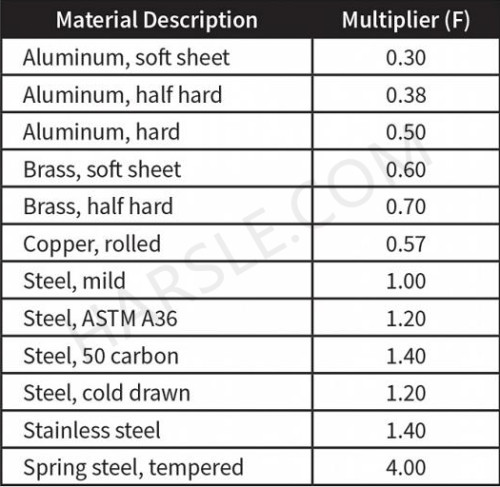

Minimum bend radius sheet metal aluminum. Aluminum is typically thicker and stronger and requires more force to bend as well as consideration of edge conditions and punch nose radii. We recommend 5052 h32 for aluminum chassis projects. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Radii for various thicknesses expressed in terms of thickness t.

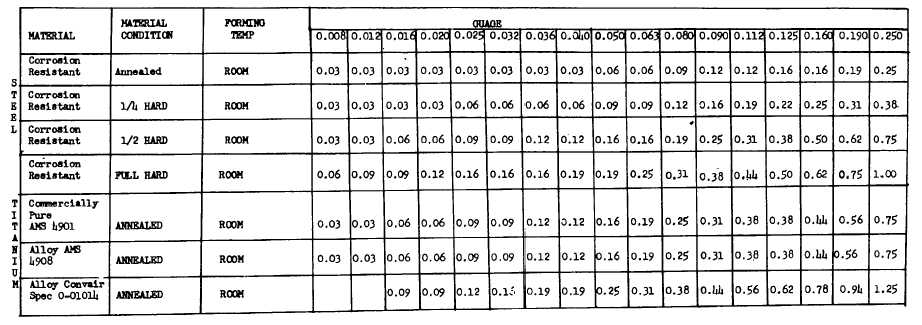

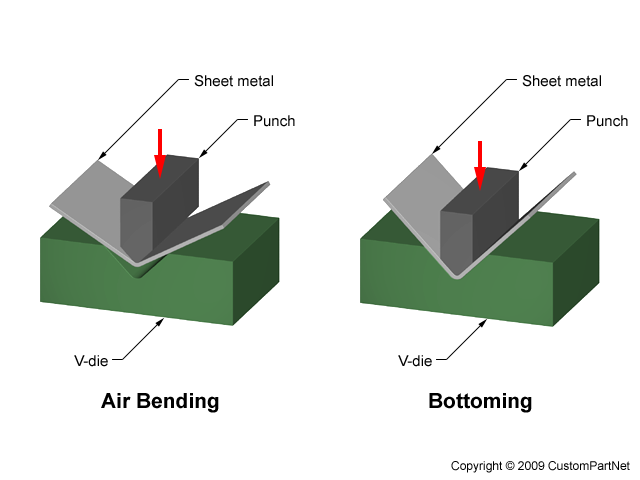

Per the aluminum association inc. Most aluminum requires considerations to ensure any bending is done using a large enough radius to ensure the material does not crack. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal. Bend radii minimum bend sizes.

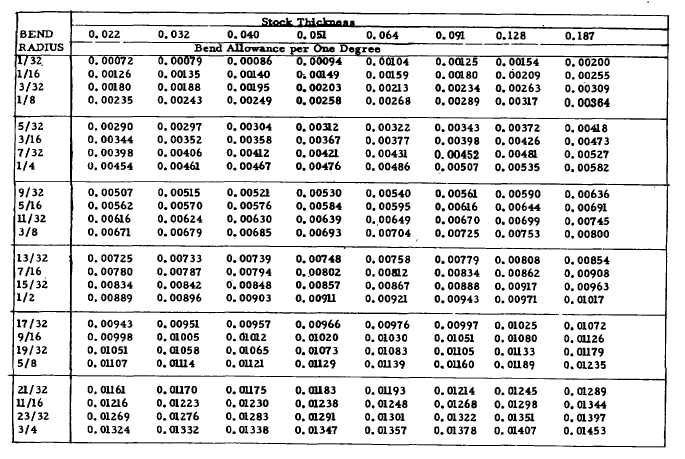

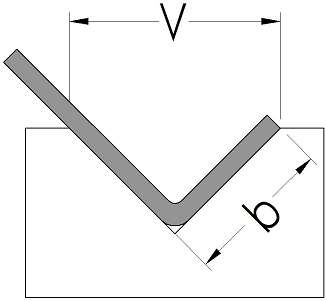

Minimum bend radius alloy 032 040 050 063 090 125 190 250 3003 h14 0 0 0 0 1 2 4 8 5052 h32 1 1 1 2 3 4 8 12 6061 t6 2 3 3 4 6 8 18 32 aluminum minimum bend radius in 1 32nds of an inch. The minimum bend radius data shown in these charts is measured to the inside of the bend. In general parts should be designed with a minimum 1t bend radius radius matching the sheet thickness for the simplest setup and to ensure we can form the intended geometry.